Any chain saw regardless of make, model or age, is only as good as the chain that is mounted on it. A properly sharpened chain will have the single biggest impact on overall cutting performance and operator safety. Unfortunately, chain sharpening is one of the least understood aspects of chain saw maintenance. Becoming proficient in chain sharpening means you must have an understanding of how a chain actually functions.

SAW CHAIN IS COMPRISED OF THREE COMPONENTS:

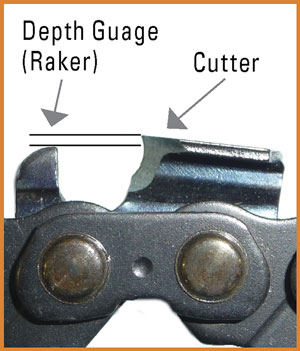

Cutters. This component is responsible for severing the wood fiber and removing the wood chip. It is the focal point when sharpening a chain.

Drive link. The drive link transmits the power of the engine to the chain. The drive link engages the sprocket on the engine and the sprocket on the guide bar tip.

Tie straps. The tie straps join all the pieces together and are the main part of the chain that makes contact with the guide bar.

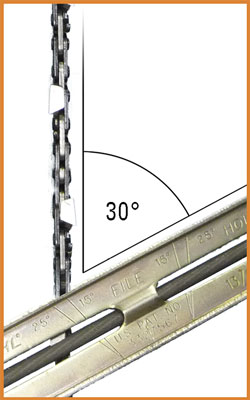

Tools required to properly sharpen a chain include: a round file, a file guide, a flat file and depth gauge tool. Different sizes and types of chains require different sizes and types of files. Before attempting to sharpen your chain, consult with your local STIHL Dealer to make sure that you have the correct tools for the job. Generally speaking, a homeowner is going to use a different style of chain than a professional faller, and each will utilize different techniques to sharpen their chains. A professional faller will use a chisel style cutter chain (RS type). This type of chain cuts approximately 25% faster than a round covered chain (RM type), but will dull quicker if subjected to dirt and debris. Properly sharpened square chisel chain requires precise corner alignment and filing angles. The level of accuracy needed is hard to duplicate by hand and is best accomplished using a chain grinder. Round filed chain is more common for consumer chain and a lot easier to sharpen. Sharpening a chain with a round file requires the proper size file and guide, and the correct filing angles. Your STIHL Dealer can provide you with the correct information to get you started.

Trying to cut wood with a dull or incorrectly sharpened chain results in a loss of power and cutting speed, an increase in fuel consumption, higher rate of wear on the guide bar, sprocket and clutch assembly and operator fatigue. A sharp chain should feed itself into the wood with very little pressure being applied. If an operator has to force the chain saw during a cut, the chain must be inspected for dull cutters or incorrect depth gauge setting.