Types of Saw Chain

STIHL manufactures many different types of saw chain for a variety of uses and purposes. While saw chain may look very similar, there are differences. It is important to understand what the differences are in order to answer “which chain should I choose when selecting chain for my application?”.

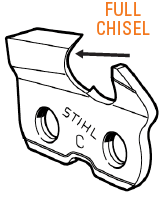

STIHL makes a series of chain that is referred to as SUPER chain. Sometimes this chain type is referred to as “full chisel” chain. The upper corner of the cutter is square.

STIHL makes a series of chain that is referred to as SUPER chain. Sometimes this chain type is referred to as “full chisel” chain. The upper corner of the cutter is square.

This “square” corner allows for faster cutting speeds when working in clean timber. However, it does tend to dull more quickly when encountering debris in the wood.

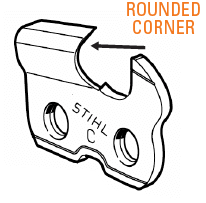

A Micro chain sometimes referred to as “semi chisel” chain has a rounded upper corner.

A Micro chain sometimes referred to as “semi chisel” chain has a rounded upper corner.

This rounded corner does slow the cutting speed, but it does withstand more debris in the wood. It is also more forgiving when sharpening, if the user makes slight errors with sharpening angles.

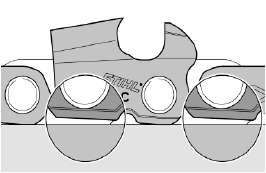

All STIHL “C” series or comfort chain has an innovative design that keeps the heel or back of each cutter raised off the guide bar when the cutter is not cutting in wood. Notice the “C” below the STIHL in the picture above. When the cutter is cutting, the cutter rocks rearward and sits squarely on the guide bar. The benefit to this type of chain is in reduced vibration, extended guide bar and chain life, and it requires less power to run the chain, leading to increased cutting speeds.

All STIHL chain is pre-stretched at manufacturing, which reduces the need for adjusting the chain as often when new. All STIHL chain is OILOMATIC®. This feature, which is exclusive to STIHL chain, has an oil way or groove designed into each drive link which directs the lubricating oil to the rivet area, the highest load point and wear point on a chain.

All STIHL chain is pre-stretched at manufacturing, which reduces the need for adjusting the chain as often when new. All STIHL chain is OILOMATIC®. This feature, which is exclusive to STIHL chain, has an oil way or groove designed into each drive link which directs the lubricating oil to the rivet area, the highest load point and wear point on a chain.

The Do’s of Chain Sharpening

Sharpening a chain is a simple task, but it does require practice and the user must follow some general simple guidelines. Each size and type of chain requires a specific size of round file to sharpen the cutters. Look at the chart on the back of the box that the chain came in. It has all the file sizes and angles listed there, or contact your local STIHL Dealer for assistance.

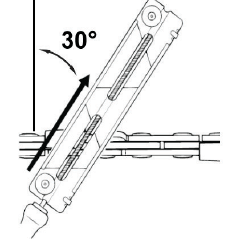

When sharpening a chain, the top of the cutter should be sharpened at a 30° angle for most applications. Hold the file guide at this angle and always file only away from you, never towards yourself. Count the number of strokes you make on each cutter and then use the same number of strokes on each cutter on the loop of chain. Keeping the cutter length equal is important to ensure a chain that cuts straight.

When sharpening a chain, the top of the cutter should be sharpened at a 30° angle for most applications. Hold the file guide at this angle and always file only away from you, never towards yourself. Count the number of strokes you make on each cutter and then use the same number of strokes on each cutter on the loop of chain. Keeping the cutter length equal is important to ensure a chain that cuts straight.

Start sharpening on the side of the chain that feels most “uncomfortable” for you since this will help keep the tooth length equal. When sharpening a chain, you must remove enough material so the top of the cutter is the same colour over its entirety. The used part of the chain appears lusterless and grey. Remove ALL this dull grey colour back to the chrome, as the chroming helps the cutter retain its edge.

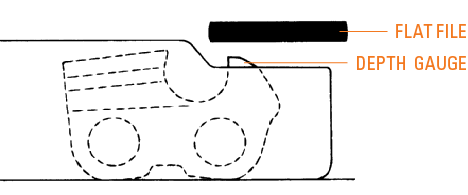

After the cutters have been sharpened, you must adjust the depth gauges (sometimes known as rackers or drags). This is done with a flat file and a depth gauge tool designed for your specific chain. Place the depth gauge tool over at least two cutters and the depth gauge will protrude through the slot if it needs to be lowered. File the depth gauge to the level of the tool. Never lower the depth gauges more than recommended, as this will cause excessive vibration, overload the chain and may cause it to break while in operation and increases the risk of kickback.

After the cutters have been sharpened, you must adjust the depth gauges (sometimes known as rackers or drags). This is done with a flat file and a depth gauge tool designed for your specific chain. Place the depth gauge tool over at least two cutters and the depth gauge will protrude through the slot if it needs to be lowered. File the depth gauge to the level of the tool. Never lower the depth gauges more than recommended, as this will cause excessive vibration, overload the chain and may cause it to break while in operation and increases the risk of kickback.

Following some simple guidelines and with practice, you can develop your skills as a saw chain sharpener. As always, your STIHL Dealer has a full line of sharpening tools and chain and can offer expertise and advice on the best way to maintain your saw chain, and which type of chain to use, ensuring that it cuts well and remains safe while operating your saw.