Have you been frustrated by trying to cut with a dull chain? Have you sharpened a chain and been unsatisfied with the results?

This short article will serve as a guide to help you sharpen your own chains so they cut like they did when they were new. It is possible to make an old dulled chain perform as well as it did when it was brand new. In order to sharpen a chain two files are needed; a flat file and a round file. A chain saw cuts by chiseling wood out of a kerf created by the left and right hand side plate cutters. When a saw stops cutting well, it is because these cutter parts of the tooth have become dulled or blunted and need sharpening. A guide is also an

important and necessary sharpening component. File guides simply help ensure that we are getting the filing angles set by the manufacturer back to their original after being dulled or blunted.

The first thing to consider in keeping your chain sharp is prevention. When someone dulls a chain it is often from cutting into the ground, known as ‘grounding’ the saw. Keep your saw chain away from abrasive materials like sand, asphalt, gravel, concrete, nails, metal, tin, drywall or charcoal. A chain saw chain will keep its edge for many cuts, days or even weeks if you are only cutting wood that is free from abrasives.

It is best to hold your chain saw firmly with both hands at all times and use your chain brake when not cutting and during starts. Use good posture and stay in a strong upright stance, when cutting low to the ground, remember to bend at your knees rather than bending over at your waist and straining your back. By using both hands and maintaining good posture and positioning you can avoid accidentally ‘grounding’ your saw. Finally, wear all necessary personal protective equipment; this includes safety glasses, chaps, helmet, gloves and

work boots.

A good B.C. logger friend of mine and Arboriculture instructor always tells our students; “sharpen your chain to keep it sharp, not to make it sharp”. What Kyle means is that it is much easier to sharpen a chain that is only slightly damaged or dull, than to sharpen one that has been continually run after being initially dulled. When a chain saw is operated dull and forced to cut, it causes more wear and deteriorates other parts of the saw as well. It is generally quite obvious or noticeable when your chain is getting dull. When you notice this

happening then it is time to stop and sharpen.

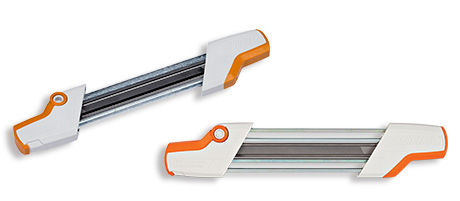

The biggest mistake I see made by people sharpening chain is not using guides. Anyone can sharpen a chain very well if they use a quality guide. Your local STIHL Dealer has a selection of guides. There is one model in particular that I have found makes sharpening fast and easy. This sharpener requires no power source and has simple instructions etched right into the handles so you’ll never lose them. In addition, the guide itself acts as a storage case and protects your files from damage when not in use.

Ask for the STIHL 2-in-1 File Holder. This system allows you to sharpen your cutters and set the depth gauge with every stroke which saves you time. It works so well, many professionals are switching over to the STIHL 2-in-1 File Holder. It is important to ask your dealer which size of file you need for your saw chain. They will give you the help you need to ensure you have the correct sized sharpening system.

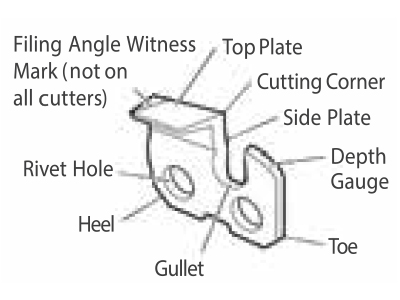

A well sharpened chain saw cutter has three areas that require attention when sharpening: 1) top plate chisel, 2) side plate cutter and 3) depth gauge chisel height. How much is chiseled is controlled by the depth gauge. When these angles and heights are filed to manufactured specifications until sharp, then your chain will cut like new regardless of how old it is.

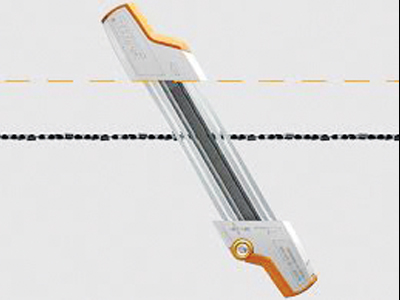

Sharpening a chain with the STIHL 2-in-1 File Holder is simple. Hold the guide flat (no angle necessary). This ensures the depth gauge flat file will work properly. Next match the angle of the guide with your bar as illustrated, this ensures you are at the correct top plate angle. Then to sharpen the cutters, push the round file through the gullet of the cutter, while simultaneously dressing the depth gauge with the flat file.

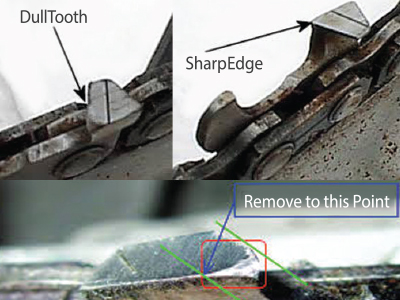

Remember these files work only on the push stroke; never draw the files back with pressure as this will dull your files. Always file on the push stroke and only use moderate pressure; an old friend of mine always says; “chain saw filing is not a muscle sport, let the file do the work”. The guide helps you ensure the angles are correct and then all you need to do is know when it is sharp. Sharp cutters will show no glare or glint on their leading edges. If there is shine or glare visible, it means that the leading edge is bent or blunted and therefore still dull. When sharp, they will be straight until they reveal no glare or reflection off of bent edges.

There are many myths, legends and facts that go around about sharpening chain, and I cannot dispel or speak to them all in this short article. I have been a professional arborist for 30 years and have been professionally training people in the safe use of chain saws, their maintenance and care for over 20 years. When it comes to sharpening, I come back to the same conclusions over and over, and my best guidance when it comes to sharpening chains is to use a file guide.

by Dwayne Neustaeter Sr., Arboriculture Canada www.arborcanada.com