Have you ever had your chain saw get pinched part way through a cut?

Have you ever completed the back-cut on a tree you were felling and find yourself pushing the

tree like an offensive lineman on the trunk to get the tree to start falling?

Wedges are one of the most underutilized tools in tree cutting. In this article, I will introduce you to

a small tool that can save you time and improve your safety. This accessory is low cost and easy

to use. Wedges prevent bar pinch when bucking, they can get a tree on its way when tree felling

and they are an excellent tool to free a saw that has become pinched in compression.

The modern wedge is made of heavy duty plastic blends that get the job done and will not damage

the chain saw’s chain or cutters in the event of accidental contact. When wedges become

misshapen or damaged from use, they should be replaced to prevent injury from small flying

plastic projectiles. Always wear safety glasses and all of your PPE whenever bucking or falling.

Falling and/or bucking wedges are not designed or suitable for splitting firewood.

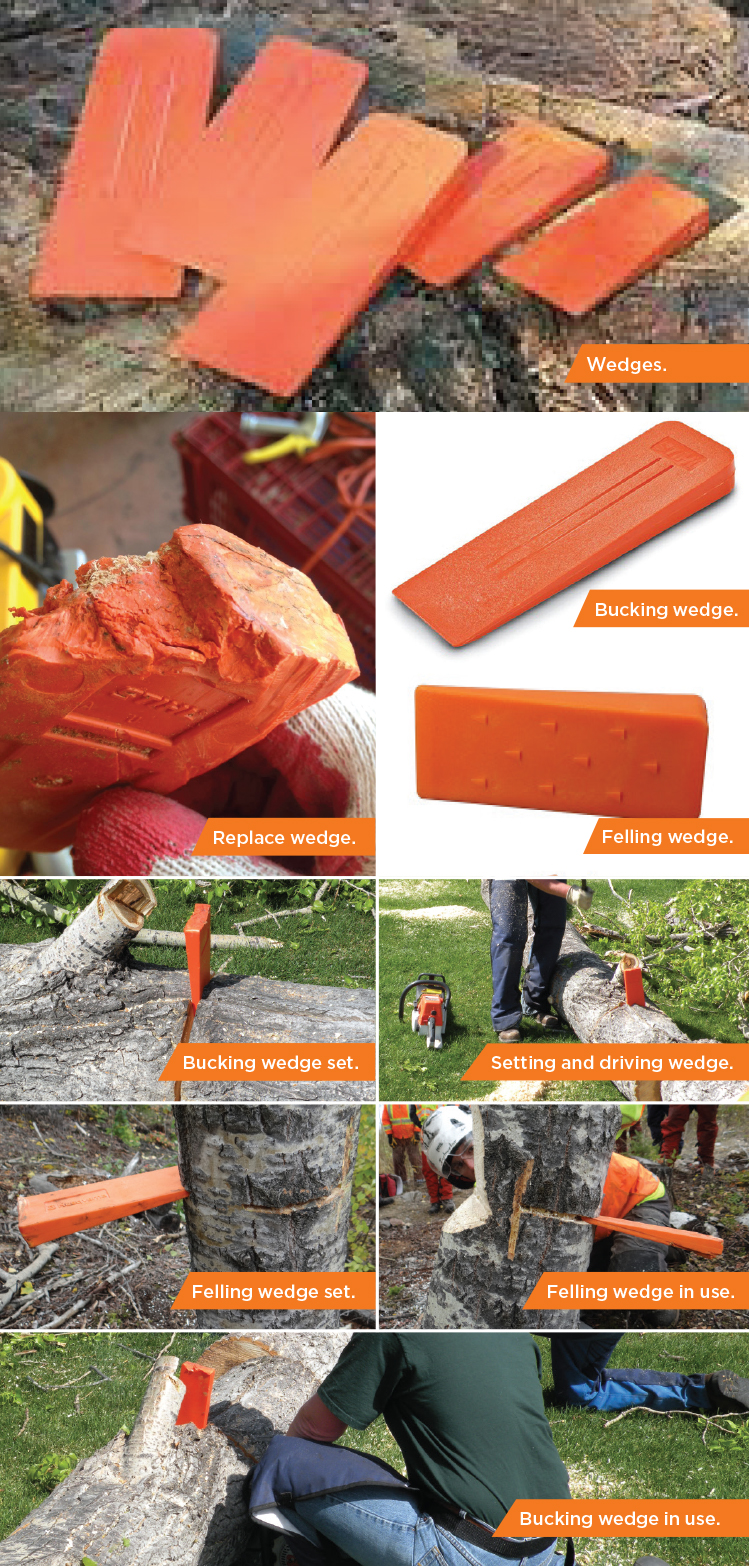

THERE ARE THREE TYPES OF WEDGES

1. Bucking Wedges - Also known as a summer wedge, bucking wedges are smooth on both sides to allow them to be easily removed from a kerf after use.2. Felling Wedges - Also known as a winter wedge, felling wedges have gripping features on one side of the wedge. These angular points are called felling ‘dogs’, in reference to the fact that they ‘bite’ into the stump. Felling wedges are placed into the back-cut of a tree being felled to help overcome slight back lean and send trees on their way, by using the mechanical advantage of ‘lift’.

3. Effing Wedges - This is the forgotten wedge and is not a wedge at all, but simply a humorous reminder to have wedges on hand when bucking and felling. When a saw becomes pinched the operator invariably is crying out for someone to help and get them an ‘effing’ wedge…the ‘forgotten’ wedge. When using bucking wedges, the wedge is placed into a saw kerf that is in the compression zone of a log. The chain saw operator must cut deep enough so that the wedge can fit into the kerf without contacting the saw chain. The wedge is ‘set’ and ‘driven’ by striking it with the back of an axe head, although hammers can work also. Once the bucking wedge is ‘set’ a bucking cut can be completed without the saw becoming pinched because the wedge prevents compression closing the kerf. It is very handy when bucking larger sized logs. (Images: Bucking wedge set and Setting and driving wedge) Felling wedges are placed and ‘set’ in the back-cut of a tree being felled in the same manner in which a bucking wedge is ‘set’. After the desired hinge thickness is cut, the saw is removed and set aside for safety. Then the faller strikes and ‘drives’ the falling wedge into the kerf, this creates a mechanical ‘lifting’ force that will move or ‘push’ the top of the tree over and thus shift the trees centre of gravitational mass over the balance point so that gravity can finish the job. Remember the felling ‘dogs’ found on falling edges must be facing downward into the stump when used for felling.

Finally, if or when your saw becomes accidently pinched, reach for your wedge, either one will do in this case. Insert the wedge as best you can into the compressed kerf and begin to ‘drive’ it in. Once the wedge ‘sets’, continue to ‘drive’ it with your axe until the kerf is opened enough that your chain saw bar can be easily removed from the now wedged open kerf. (Image: Bucking wedge in use) Bucking and falling wedges are readily available from your local STIHL Dealer and they come in various lengths to accommodate different diameter of trees or logs. One last important note; in most jurisdictions, it is a mandatory regulation that when trees are being felled that wedges be within reach of all workers. Belts with pouches and holders are often used by professional tree workers and timber fallers. This makes it easy for them to carry wedges and an axe among some other things like a first-aid kit, sharpening and maintenance tools.