If you work on a construction site, you’ll know that delivering a fast, quality result is what really counts. The dynamic TS 500i with STIHL Injection is the workmate you always hoped for. Powerful, lightweight and well-balanced, it combines precision, efficiency and user-friendliness with cutting-edge technology. So you can focus on the task at hand.

• Electronically controlled fuel-injection technology – first of its kind in the industry

• Increased power by 17% while only increasing weight by 6%, as compared to the STIHL TS 420

• Low-emission engine provides optimal torque throughout RPM range

• Simplified starting procedure eliminates the need for a choke

• Lightweight, compact and well-balanced design increases user comfort

• Electronic water control feature simplifies water flow adjustment while cutting

• X2 air filtration system is virtually maintenance-free while maintaining an incredible 99.96% cleaning efficiency

| SPECIFICATIONS | |

|---|---|

| Displacement | 72.2 CC |

| Power Output | 3.9 KW |

| Weight ① | 10.2 KG/22.5 LB |

| Max. Wheel Size | 14"/350 MM |

| Max. Cutting Depth | 4.9"/125 MM |

| ① Weight without fuel and cutting wheel. | |

SENSOR

The sensor measures the temperature and pressure in the crank chamber. This information is then transmitted to the control unit.

GENERATOR

The generator produces all the electricity required to power the control unit and operate the cut-off saw. And it does this right from the first rotation of the crankshaft during start-up. But that’s not all: while the tool is running, the generator continually updates the control unit about the position of the crankshaft and the current engine speed.

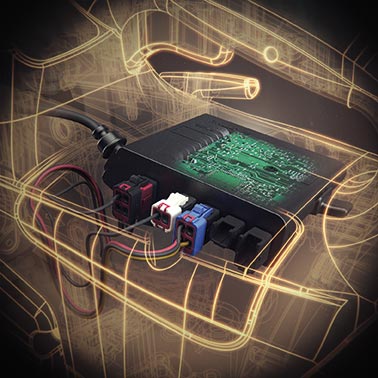

CONTROL UNIT

The control unit is the most crucial part of the STIHL Injection system. It calculates the air mass, i.e. the load on the machine, using data from the sensor regarding the current temperature and pressure. Together with the engine speed information supplied by the generator, it can accurately determine the amount of fuel, as well as the optimal ignition timing and duration. As a result, the fuel injector and ignition are always triggered at just the right moment.

FUEL INJECTOR

The fuel injector injects the exact amount of fuel calculated by the control unit directly into the crankcase, at precisely the right point in the combustion cycle.

FUEL INJECTION PUMP

The fuel injection pump keeps the fuel pressure constant. This guarantees that the fuel injector is always supplied with sufficient fuel at just the right pressure.